Top 10 OSHA Violations In 2016 And How To Avoid Them

Occupational Safety and Health Administration (OSHA) recently announced preliminary results for its most frequent violations at the National Safety Council (NSC) Congress & Expo.

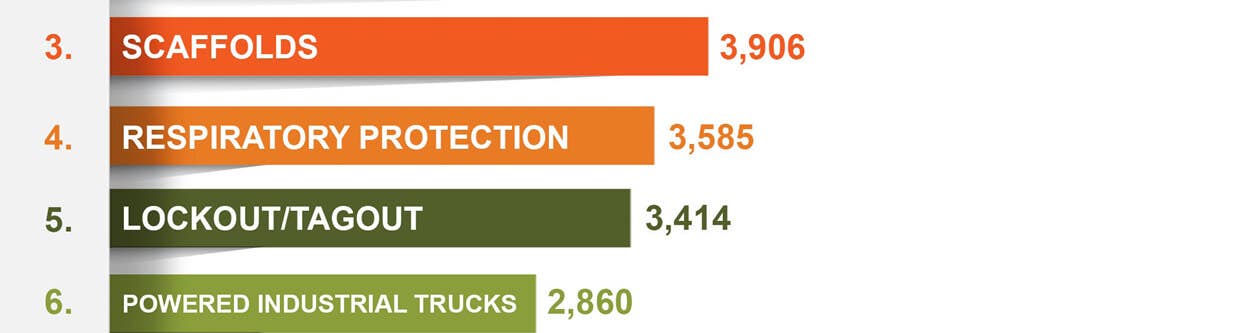

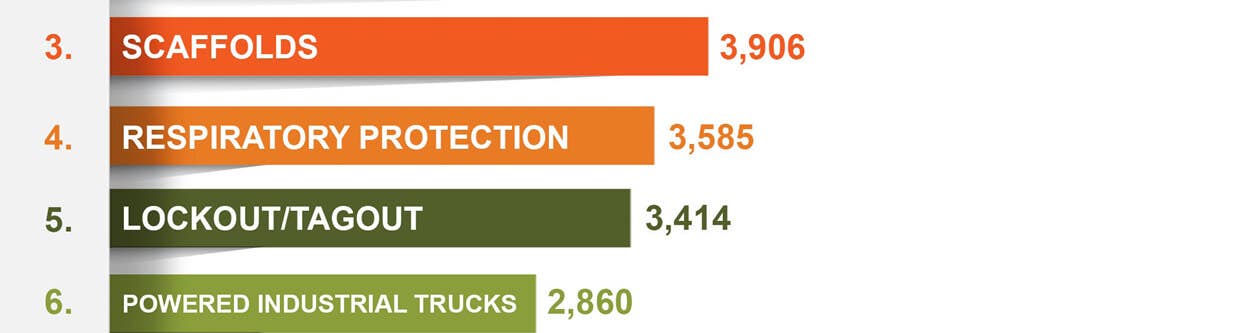

The top 10 OSHA violations for 2016 include:

1. Fall Protection 501: this standard specifies where fall protection is required as well as the proper installation of safety systems to prevent falls in Construction.

2. Hazard Communication 1200: OSHA’s Hazard Communication Standard (HCS) requires development and distribution of information for employees regarding the hazards of chemicals used in the workplace, in the form of labels and safety data sheets (SDS), as well as adequate training for employees to thoroughly understand hazard chemical exposure risks.

3. Scaffolds 451: this standard outlines the requirement for implementing and accessing scaffolds in Construction.

4. Respiratory Protection 134: this standard addresses preventing occupational diseases caused by atmospheric contamination such as harmful dusts, fogs, fumes, gases, smokes and sprays.

5. Lockout/Tagout 147: companies were mostly given citations for improperly training employees on lockout/tagout procedures, not having a lockout/tagout procedure in place or lacking periodic inspections of existing procedure.

6. Powered Industrial Trucks 178: this standard addresses safety requirements relating to operation of powered industrial trucks, commonly called forklifts or lift trucks.

7. Ladders 1053: hazards in this category are mostly associated with improper use of portable ladders in Construction, likely due to inadequate training.

8. Machine Guarding 212: Moving machine parts could cause severe injuries such as crushed fingers, hands, amputations, burns, or blindness, hence necessary safeguards and safety training are required to eliminate these various hazards.

9. Electrical Wiring 305: citations are commonly issued for unsafe substitutes for permanent wiring and incorrect use of extension cords

10. Electrical, General Requirements 303: improperly installed or incorrect use of electric equipment, and obstructed working space around electric equipment commonly lead to OSHA citations in this category.

“In one year, over 10,000 severe workplace injuries will be reported to OSHA, and almost half of those will be fatalities” – said Cathy Evans, ClickSafety Corporate Account Manager, in the National Electrical Contractors Association (NECA) podcast – “They can all be prevented if people had the information and knowledge to keep themselves safe. When these tragedies are investigated, we often find out that the workers weren’t trained. They didn’t have the information they need.”

Workers’ safety and health should always be companies’ number one priority. To ensure that workers are going home unharmed every night, companies must not only have an effective safety training program, but also focus on building a strong safety culture. “It’s not easy to build a strong safety culture, and it’s not easy for a safety director or business leader to do it all,” Evans stated. Every employee should be responsible for safety.

When asked to give advice for companies working to build effective safety culture, Evans suggested, “Take it very seriously for your business because if you’re not, it has tremendous impact on your business. We’d want to make sure that you’re performing job hazard analysis for your workers. And if you don’t have somebody who’s qualified to do that within your company, consult with a third-party safety organization. If you put someone in charge of safety for your organization, such as a safety director, make sure you’re not just assigning it to somebody who just started with your company, but rather somebody who really is qualified and has the credentials."